A Record of Metal & Flame Welding Blog

More Guides

-

How to Choose a Cutting Wheel

Jan 23, 2026, 15:24 PM by Ann McCallum-BolesChoosing the right cutting wheel is key to clean, efficient welding. Your choice depends on wheel type, grain, and thickness. Type 1 wheels offer sharp, precise cuts with a flat profile, while Type 27 wheels improve visibility and allow flush cutting. Ceramic alumina, zirconia, aluminum oxide, and silicon carbide each fit different metals and demands. Thickness affects accuracy and durability. Match the wheel to your grinder, material, and project to get smoother cuts and avoid rewelding.Full story -

How Can Robotic Welding Transform Fabrication Processes?

Oct 28, 2025, 09:26 AM by Ann McCallum-BolesRobotic welding is reshaping modern fabrication by delivering faster production, lower costs, and higher-quality results. This blog explores how welding automation can streamline your workflow, reduce waste, and elevate product consistency. Whether you're considering a switch or scaling up, discover why robotic welding is a smart investment for competitive manufacturing.Full story -

How Welding Positioners Can Help Improve Productivity, Quality, and Workplace Safety

Aug 14, 2025, 10:53 AM by Ann McCallum-BolesWelding positioners are crucial tools for modern fabrication, improving productivity, quality, and safety. By securely holding and rotating workpieces, they enable welders to create cleaner, more uniform welds, reducing inconsistencies and material waste. These tools also enhance worker safety by minimizing heavy lifting and improving ergonomics. Ultimately, positioners streamline workflows, reduce downtime, and are a key investment for any shop aiming to boost efficiency and consistency.Full story -

What Is Flux Core Welding Wire?

Aug 4, 2025, 11:32 AM by Ann McCallum-BolesFlux-cored welding wires, filled with flux, offer versatility and high deposition rates, making them ideal for industries like shipbuilding, construction, and outdoor repairs. Available in gas-shielded and self-shielded types, they provide strong, reliable welds and are beginner-friendly. Benefits include portability, strength, and adaptability across materials, though slag removal is required. WeldingSupply.com offers an extensive selection and expert guidance to help you choose the right wire for your project and achieve optimal results.Full story -

How to Choose a Plasma Cutter

Jun 17, 2025, 16:56 PM by Ann McCallum-BolesChoosing the right plasma cutter ensures precise, efficient metal fabrication. Key factors include material thickness, which affects amperage needs, input power (115V, 230V, or dual voltage for flexibility), and duty cycle, which determines how long the machine can run before cooling. Portability matters if you work in different locations, while operating costs like consumables impact overall expense. Plasma cutters offer speed, accuracy, and versatility. Find expert tools at WeldingSupply.com!Full story -

The History of Welding

Mar 18, 2025, 16:58 PM by Ann McCallum-BolesWelding is key in today's world. It helps build everything from skyscrapers and ships to airplanes and new medical technology. Welding has greatly influenced humanity and its impact reaches far into the past and over centuries. It highlights our endless quest for innovation and progress. By looking at welding's origins, key milestones, and modern advancements, we see how this craft has influenced society for thousands of years.Full story -

The Benefits of Automated Welding: Revolutionizing Fabrication Processes

Mar 3, 2025, 14:08 PM by Ann McCallum-BolesAutomated welding utilizes machines and computer programs to help make welding faster and more consistent. These systems follow set instructions to complete welding tasks with less help from people, which may reduce errors and improve efficiency. By keeping weld quality more uniform, automated welding can support better results across large projects. While outcomes can vary, many manufacturers use automation to meet production goals and stay competitive.Full story -

Welding Accessories for Beginner Welding

Feb 13, 2025, 09:54 AM by Ann McCallum-BolesThis guide serves as a starting point for beginner welders, detailing the essential tools and accessories required to ensure safety, precision, and efficiency during the welding process. We'll walk you through the key facets of welding—from material preparation and workspace setup to selecting the proper equipment and consumables for different welding methods such as MIG, TIG, and stick welding. We'll also discuss the importance of post-weld cleanup to achieve durable, high-quality results.Full story

What Is Flux Core Welding Wire?

Choosing the right welding wire is critical for achieving strong, reliable, and defect-free welds. Among the many options available, flux core welding wires are well-known for their versatility and performance. Whether you're working in heavy-duty

industries such as shipbuilding and construction, or you're tackling smaller projects like farm repair, flux core welding wires can offer unique advantages that set them apart from other filler materials.

In this guide from WeldingSupply.com, we’ll share information you need to know about flux core welding wires, including their construction, different types, popular applications, and some best practices. With this knowledge, you’ll be better equipped to make informed decisions and take your welding projects to the next level.

This guide is not a replacement for in-person instruction. You should always seek instruction from a qualified trainer. However, here are some tips to help you get started.

Table of Contents:

→ What Is Flux Core Welding Wire?

→ What Is the Role of Flux in Welding?

→ Types of Flux Core Welding Wire

→ Advantages of Flux Core Welding Wire

→ Disadvantages of Flux Core Welding Wire

→ Applications of Flux Cored Welding

→ Best Practices for Using Flux Core Wire

→ Frequently Asked Questions About Flux Core Welding Wire

The Basics: What Is Flux Core Welding Wire?

Unlike solid welding wires, flux core wires have a tubular structure with a hollow center, which is filled with flux—a combination of deoxidizers, alloys, and other chemical compounds. Flux can play a vital role in the welding process, including cleaning the weld and protecting the weld pool from contaminants that could cause defects like cracking, porosity, or weak fusion points.

Flux core wires are used in flux core Arc Welding (FCAW), a semiautomatic or automatic welding process. FCAW combines the benefits of high productivity, portability, and ease of use, making it popular in a wide range of industrial applications. Both novice and seasoned welders appreciate the flexibility and efficiency that flux core wires can provide, especially when faced with challenging environments.

What Is the Role of Flux in Welding?

The flux inside the wire is what makes flux core welding unique. During the welding process, the intense heat causes the flux to melt and react chemically, creating a protective gas shield over the molten weld pool. This shield prevents oxygen, nitrogen, and other atmospheric contaminants from interacting with the weld, which helps to minimize defects and to create a strong, high-quality welded joint.

The flux also contributes to the creation of slag—a residue that forms on the weld surface after cooling. While this slag requires removal after welding (a step we’ll dive into later), it’s an essential part of the process for many applications, as it can enhance the protection of the weld during cooling.

Types of Flux Core Welding Wire

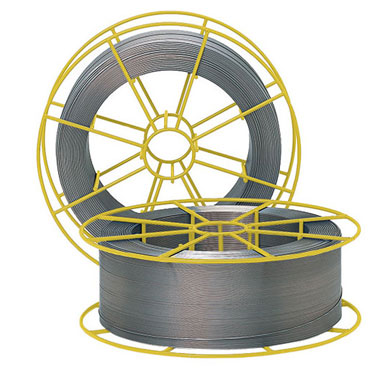

Flux core wires come in two main types: gas-shielded flux core wires and self-shielded flux core wires. Each type serves specific needs, so understanding their differences is critical in choosing the right wire for your project.

Gas-Shielded Flux Core Wire

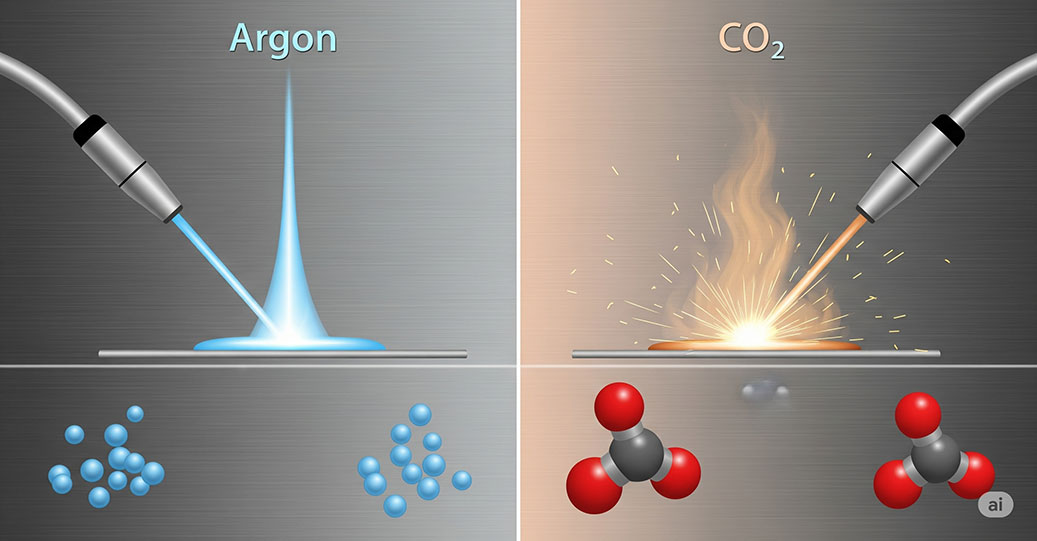

Gas-shielded flux core wires require an external shielding gas source to protect the weld from atmospheric contamination. Popular shielding gases include carbon dioxide (CO₂) or a mix of argon and CO₂.

Pure CO₂ Shielding:

Using pure CO₂ provides excellent penetration, making it ideal for thicker materials. However, this setup tends to produce higher spatter levels, requiring additional cleanup. Wires made specifically for CO₂ shielding include a “C” in their designation, such as E71T-9C-H8.

Argon/CO₂ Blends:

A mix of argon and CO₂ typically results in a smoother arc, better weld quality, and reduced spatter. These wires are marked with an “M” designation, such as E71T-9M-H8. Some wires can work with both gas types and carry designations like E71T-9C-H8/E71T-9M-H8.

Gas-shielded wires are best suited for indoor workspaces or controlled environments where wind and other external factors won’t disturb the shielding gas around the weld.

Self-Shielded Flux Core Wire

Self-shielded wires generate their own protective gas during the welding process, eliminating the need for external shielding gas. This is made possible by the formulation of the flux, which melts and chemically reacts to produce a gas shield to protect the molten weld puddle.

Because these gasless wires don’t depend on gases and the cylinders that contain them, self-shielded wires are portable and convenient. They’re perfect for outdoor environments, where windy conditions could easily scatter externally supplied shielding gas. Self-shielded wires are commonly used for construction, pipeline repairs, and other applications where portability and weather resistance are paramount.

Advantages of Flux Core Welding Wire

Flux core welding wires can feature several advantages, which explain their popularity in diverse industries. These benefits include:

High Deposition Rates

Flux core wires can allow for higher deposition rates compared to welding methods like stick welding or solid wire welding. This is dependent upon the base metal, wire chosen and environmental conditions, as well as the welder’s skill level. This can allow for faster completion of welds, which is important for projects with tight deadlines.

Versatility Across Materials

Flux core wires are available for a wide range of base metals, including carbon steel, low-alloy steel, stainless steel, nickel alloys, and even cast iron. Whether you’re working on structural welding, ship repairs, or stainless-steel, there’s likely a flux core wire tailored to your specific need.

Forgiving Process

Unlike processes like TIG welding, which can have a steep learning curve for some, flux core welding is relatively easy to learn. Even beginner welders can achieve good results after some practice. flux core welding is also more forgiving of minor dirt, rust, or mill scale on the base metal, though cleaning before welding is always recommended for the best results.

Excellent Strength and Toughness

flux core wires deliver welds with tensile strength and impact resistance values for everyday needs, as well as for critical service needs. This makes them suitable for applications including heavy machinery, structural steel, and pipelines.

Portability for Outdoor Work

Self-shielded flux core wires are a good choice for outdoor projects. With no need for external shielding gas, welders can work in windy conditions that would render other welding processes ineffective.

Disadvantages of Flux Core Welding Wire

Like any welding process, flux core wires also come with certain drawbacks that should be considered:

Slag Removal

Both gas-shielded and self-shielded flux core wires produce slag that must be chipped away or brushed off after welding. Depending on the complexity of the project, this post-weld cleanup can add to the overall time required.

Higher Cost per Pound

Flux core wires typically have a higher cost per pound compared to solid wires. However, given their higher deposition rates and suitability for challenging environments, this added cost can be outweighed by their advantages.

Limited Use on Thin Materials

Flux core welding is particularly well-suited to thicker materials. For thinner metals, there’s a risk of burn-through, distortion, or warping due to the process’s high heat input.

Applications of Flux Core Welding

Flux core welding is used across a myriad of industries and applications. Its versatility and adaptability make it a a good choice for both indoor and outdoor welding tasks. Some common applications include:

Shipbuilding

In shipyards, the high deposition rate of flux core welding is essential for welding thick steel plates. It’s also effective in the various positional welding required for constructing ships.

Structural Steel Fabrication

Buildings, bridges, and other structures often rely on flux core welding due to its ability to produce strong, high-quality welds quickly and efficiently.

Heavy Equipment Repair

From farm machinery to manufacturing equipment, flux core wires excel in repairing thick, heavy-duty materials. Self-shielded wires are successfully used for field repairs in remote locations.

Pipeline Welding

Flux core wires can be used for constructing and repairing pipelines, especially in outdoor environments where conditions are challenging.

Industrial Manufacturing

In production environments where speed and precision are critical, flux core welding is widely used to weld a variety of metals.

Best Practices for Using Flux Core Wire

To get the best results from flux core welding wires, follow these tips:

Ensure Proper Polarity:

Most flux core wires require a specific DC polarity. Check the manufacturer’s specifications to avoid performance issues.Clean Your Base Metal:

While flux core wires are more forgiving of surface contamination, removing dirt, grease, and rust will lead to better results.Select the Right Wire Diameter:

Match the wire diameter to the thickness of the material being welded and the amperage capabilities of your welding machine.Control Your Travel Speed:

Maintain a consistent and appropriate travel speed to prevent weld defects.Store Wires Properly: Moisture can compromise a wire’s performance. Store flux core wires in a dry environment and protect them from humidity.

Why Buy Flux Core Wire from WeldingSupply.com?

|

|

|

|

| Stainless Steel Flux Core Wire | Mild Steel Flux Core Wire | Alloy Steel Flux Core Wire | Hard Facing Flux Core Wire |

At WeldingSupply.com, we understand that every welding project is unique. That’s why we offer a wide selection of flux core wires for various base metals, thicknesses, and environmental conditions. Whether you need gas-shielded or self-shielded wires, carbon steel or stainless-steel fillers, we’ve got you covered. Our knowledgeable team is here to offer personalized guidance, helping you choose the right wire for your specific needs. Visit our website to browse our products or contact us directly for expert advice.

Conclusion

Flux core welding wires are versatile, offering high deposition rates, portability, and good performance across a variety of environments and applications. Whether you’re a professional welder or a hobbyist, understanding the types, applications, and advantages of flux core wires gives you the knowledge you need to make the most of this powerful welding tool.

Explore the extensive selection of flux core welding wires at WeldingSupply.com and find the perfect solution for your next project. Let us help you weld with confidence and achieve top-notch results every time.

NOTE

Shop Flux Core Welding Wire →

Frequently Asked Questions About Flux Core Welding Wire

What is the main difference between flux core welding wire and solid welding wire?

What are the two main types of flux core welding wire?

The two main types of flux core welding wire are:

-

Gas-Shielded Flux Core Wire: This type requires an external shielding gas (typically CO₂ or an Argon/CO₂ blend) to protect the weld. It's best when welding indoors or in controlled environments.

-

Self-Shielded Flux Core Wire: This wire generates its own protective gas from the flux, eliminating the need for an external gas cylinder. It's highly portable and ideal for outdoor or windy conditions.